Home » Steel Fabrication » Top 10 Innovations in Steel Fabrication: How Allied Steel is Leading the Way

Share this Blog Post

Top 10 Innovations in Steel Fabrication: How Allied Steel is Leading the Way

Steel fabrication is an endlessly innovating industry, continually enhanced by technological advancements and precise methodologies. Allied Steel stays ahead of the curve in these developments, offering unparalleled expertise in cutting-edge techniques like plasma cutting and welding. Join us as we dive into the top 10 innovations in steel fabrication, highlighting how Allied Steel integrates these technologies to deliver high-quality, precise, and reliable products to our customers.

1. Precision Plasma Cutting

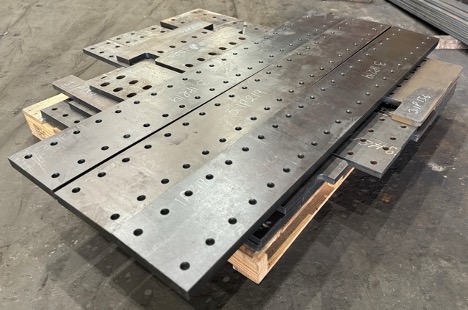

One of the most transformative techniques in steel fabrication, precision plasma cutting, enables fabricators to cut through thick steel with remarkable accuracy. At Allied Steel, our new plasma cutting machine is equipped to handle a variety of complex tasks. From connection plates used in steel erecting to custom parts for machinery, our machine achieves precise cuts that support everything from structural stability to efficient installation.

In a recent project, we used ½-inch steel plates to fabricate custom hat channels for a client. Our plasma cutter created perfectly sized plates with precise hole placements, ready to be bent and tailored to meet the unique demands of the project.

2. Automated Welding

Automated welding has elevated the consistency and durability of welds, particularly in projects requiring repeated, exact welds for enhanced stability. Our team at Allied Steel applies both manual and automated welding techniques to ensure every weld meets strict safety and longevity standards, from machinery components to high-load structural frames.

3. CNC Technology for Enhanced Accuracy

Computer Numerical Control (CNC) technology is integral in modern steel fabrication, as it improves accuracy and efficiency across many processes. Our CNC-equipped plasma cutter ensures that each project we undertake meets the precise specifications needed for easy and accurate assembly, even for complex structures.

4. Advanced Steel Bending Techniques

What was once a demanding task, steel bending has been refined through advanced machinery that allows for accurate bends without compromising structural integrity. An example of our work includes using steel bending techniques on plasma-cut plates to create custom hat channels, tailored specifically to our client’s design. This approach enables us to handle projects with intricate designs and tight tolerances.

5. 3D Modeling and Simulation

3D modeling enables our team to visualize projects in intricate detail, reducing potential on-site challenges. With simulation, we assess the feasibility of custom designs and structural requirements, refining our fabrication plans before starting the cutting process.

6. Smart Marking for Field Installation

At Allied Steel, we incorporate smart marking on parts like connection plates to enhance the efficiency of installation. Each plate is marked with a unique drawing number that corresponds to the customer’s blueprints, making the entire process more productive on-site. In a recent project, ¾-inch steel connection plates were accurately marked to help our customer quickly identify where each piece belonged, ensuring smooth installation and structural stability.

7. Laser Cutting for High Precision Jobs

While plasma cutting is ideal for thicker steel, laser cutting shines in high-precision jobs, especially for thin-gauge steel and intricate designs. This technology enhances our plasma cutting and increases our capability to serve customers needing detailed cuts and designs.

8. Base Plates for Structural Integrity

For constructing table frames, accurately creating connection and base plates that fit perfectly is essential. At Allied Steel, our plasma cutting machine produces base plates with exact hole placements, ensuring that bolts line up correctly for seamless installation. This innovation supports a smooth build process and also boosts the longevity and stability of the structure.

9. Metal Additive Manufacturing

Additive manufacturing, or metal 3D printing, is gradually becoming part of steel fabrication. This technology, though still primarily used for smaller projects, offers exciting possibilities for creating custom shapes and reducing material waste. At Allied Steel, we are closely monitoring this trend as it develops.

10. Sustainability in Steel Production

Sustainability has become a key component of innovation. At Allied Steel and many other steel fabrication companies focus on eco-friendly practices, such as recycling scrap material and using energy-efficient machines. These initiatives help reduce our environmental impact while ensuring cost-effective production.

The Importance of Precision in Building Strong Frames

Every project relies on precise specifications and exact measurements to build durable, secure structures. In constructing steel frames, a minor misalignment can extend installation time and potentially weaken the frame’s integrity. By prioritizing precision, we guarantee that each hole and cut will align exactly as designed, resulting in a strong, reliable structure that meets the highest safety standards.

Conclusion

Steel fabrication is an ever-evolving field, and Allied Steel is committed to incorporating these innovations into our processes. From plasma cutting and automated welding to smart marking and advanced bending techniques, our dedication ensures that our clients receive the best in custom steel fabrication. Whether it’s structural components, connection plates, or custom parts for unique applications, Allied Steel provides the expertise and cutting-edge technology to every project for unmatched precision, quality, and strength.