Home » Steel Fabrication » The Demand for High-Strength and Corrosion-Resistant Steel Alloy

Share this Blog Post

The Demand for High-Strength and Corrosion-Resistant Steel Alloy

Meeting the Demand for High-Strength and Corrosion- Resistant Steel Alloys

In today’s construction and fabrication industries, durability and longevity are crucial. High-strength and corrosion-resistant steel alloys are vital in creating structures that stand the test of time. At Allied Steel, we meet this demand using techniques like hot-dip galvanizing steel, ensuring that our products exceed industry standards.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing steel is a process where fabricated steel is submerged in molten zinc, creating a strong, corrosion-resistant steel coating. This protective layer bonds to the steel, forming a durable barrier that prevents rust and ensures the product’s longevity, even in the harshest environments.

The galvanizing process includes:

- Surface Preparation: Steel is cleaned to remove dirt, oil, and mill scale through a series of caustic cleaning, pickling, and fluxing.

- Immersion in Molten Zinc: The steel is dipped in a bath of molten zinc at around 840°F, coating every surface.

- Cooling and Inspection: Once removed from the zinc bath, the steel cools, forming a robust zinc-iron alloy coating that protects against corrosion.

Real-World Galvanized Steel Applications

Galvanized steel applications are a cornerstone in numerous industries, valued for their outstanding strength and resistance to environmental wear. Here are some key examples:

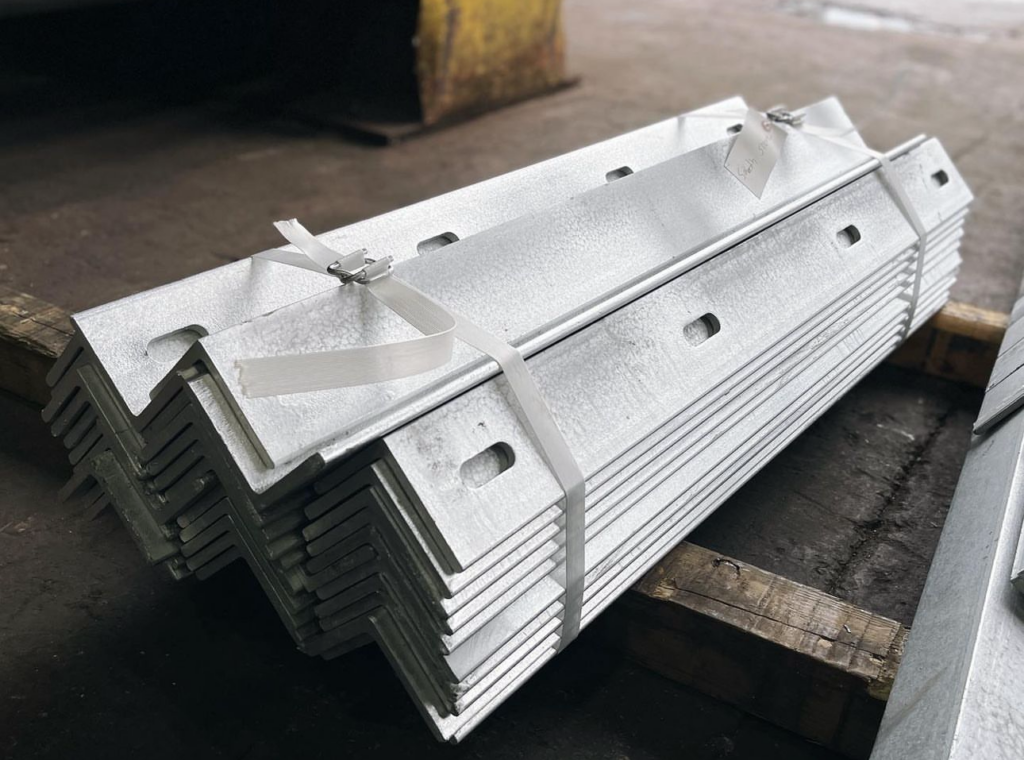

- Parking Garages: Galvanized steel angles are essential in structural repair applications, providing rust resistance in outdoor environments. For example, Allied Steel fabricated 4”x4”x3/8”x36” galvanized angles with slot holes for a New York City parking garage project, ensuring the structure’s longevity and safety.

- Outdoor Infrastructure: Fencing, guardrails, and bridges utilize galvanized steel applications to withstand the harsh conditions of rain, snow, and humidity to prevent rusting and corrosion.

- Maritime Industry: Galvanized steel applications are essential in marine environments where exposure to saltwater speeds up corrosion. From docks to shipbuilding, it serves countless purposes.

- Concrete Repairs: Zinc-coated steel reinforcements ensure durability in repairing concrete structures, particularly in areas exposed to moisture or deicing salts. Hot-dip galvanizing steel also helps prevent rust stains from occurring on surrounding concrete areas near the steel.

- Residential Construction: Allied Steel recently completed a project consisting of galvanized angles for an apartment building in New York City. In this project, the galvanized angles were used as lintel angles to prevent rusting and the staining of the surrounding masonry work.

The Allied Steel Advantage

At Allied Steel takes pride in providing customized solutions that meet the unique challenges of every project. With our focus on top-grade materials and advanced processes like hot-dip galvanizing steel, our products consistently set the standard for performance.

Whether it’s fabricating structural steel for large-scale urban developments or creating custom pieces for maritime applications, Allied Steel is at the forefront of innovation in corrosion resistant steel and strength.

Allied

High-strength, corrosion-resistant steel is no longer a luxury—it’s a necessity in modern construction and fabrication. Through hot-dip galvanizing steel, Allied Steel ensures that every product we deliver is built to last, regardless of its environment.

Stay tuned for more updates and project highlights as we continue to meet the industry’s demand for durable, dependable galvanized steel solutions for every application.